Environmental Control forCleanroom Die-CuttingPrecision Manufacturing

Does your custom die-cut medical part or sensitive electronics assembly require a clean room manufacturing environment?

Do you commonly run across product requirements that include terms like HEPA filtration, humidity and temperature control, and static mitigation?

Are extremely tight tolerances, island placement, and multiple layers of construction must-haves?

Capabilities Overview

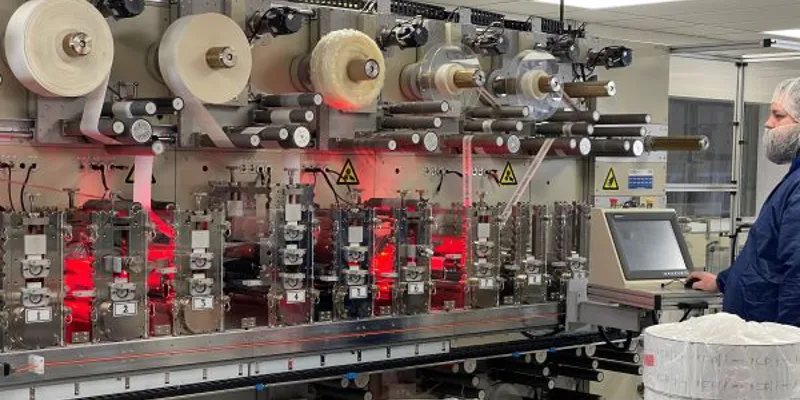

Monaatco Foam offers four ISO 8/Class 100,000 certified clean room manufacturing environments, equipped with high-speed rotary die-cutting presses. These rooms meet strict standards for industries like Medical, Electronics, Pharmaceutical, Health & Beauty, and Aerospace, ensuring low particulate, temperature- and humidity-controlled, sanitary conditions for precise, high-quality production.

Rotary Die-Cutting

Cut complex parts to very tight tolerances with low particulate levels necessary for medical and electronic applications.

In-Line Multi-Layer Lamination

Maximize productivity by combining multiple materials together and produce a complete die-cut product in one pass.

Island Placement

Reduce material waste and save money with precise web tension that ensures accurate placement at higher speeds.

Automatic Defect Detection

Eliminate gaps typically created by removal of faulty parts with inspection cameras at the end of the machine.

Clean Room Die-Cutting benefits

Quality. Consistency. Control.

Our ISO 8/Class 100,000 clean room ensures strict control over air quality, humidity, static charge, and temperature, eliminating potential environmental failure modes. This allows us to consistently produce, package, and assemble high-quality, sensitive die-cut parts. One clean room features a 10-station Dorey Converting Systems (DCS) rotary die-cutting press, designed for high-speed, precision production of multi-layer laminated components using medical-grade materials like adhesive tapes, foams, and films.

Clean Room Die-CuttingIndustries & Applications

Clean room manufacturing is essential when environmental factors like airborne particles, static, humidity, and temperature can compromise product performance. Contaminants such as dust or biological particulates, along with temperature fluctuations and static, can affect materials and lead to part rejections or even assembly malfunctions.

Medical Clean Room Die-Cutting

- Device attachment

- Wound care

- Drug delivery

- Monitoring electrodes

- Diagnostic components

- Blood filtration cartridge

- Surgical tool packaging

- Ostomy rings

- Tape sutures

- Pulse oximetry tapes

Electronics Clean Room Die-Cutting

- Bluetooth headphones EMI shielding gaskets

- Smartphone camera lens mounts

- CPU thermal interface materials (TIMS)

- Outdoor camera anti-vibration seal

- Speaker mesh gaskets

Automotive Clean Room Die-Cutting

- Headlamp seal

- Interior display touchscreen protection

- EV battery compression pads

- Rear view camera lens assemblies

- Cabin HEPA filtration cartridges

- Dashboard LED gauge cluster displays