Die Cut Solutions for

Electric Vehicle Batteries

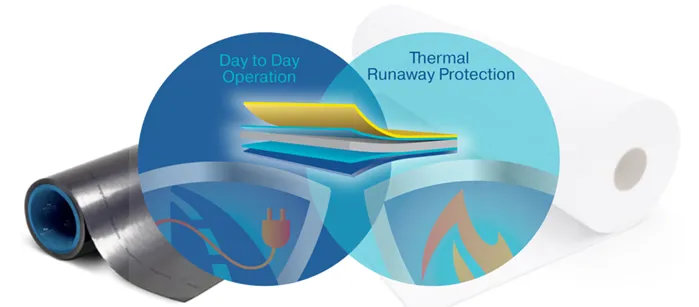

Whether you need to prevent thermal runaway propagation, seal out air, spread heat, shield heat, fill gaps, or cushion battery cells, we can help. As a specialized die-cutter and flexible materials converter, we convert performance materials into custom components that solve a myriad of challenges for electric vehicle battery manufacturers as well as ICE, autonomous, and electric vehicle OEMs.

Manage EV Battery Heat & Noise With Die-Cut Components

The electric vehicle industry is evolving quickly, and design engineers are diligently working to cut costs, reduce charging times, extend driving ranges and operating temperatures, and improve battery safety. Scientists are also hard at work developing new materials for the EV market, formulated for better temperature resistance, improved durability, and higher overall performance to weight ratio.

As a leading materials converter, we are doing our part by providing vehicle OEMs and tier suppliers with full product lifecycle support – everything from early-stage R&D and rapid prototyping to full volume die-cut production parts.

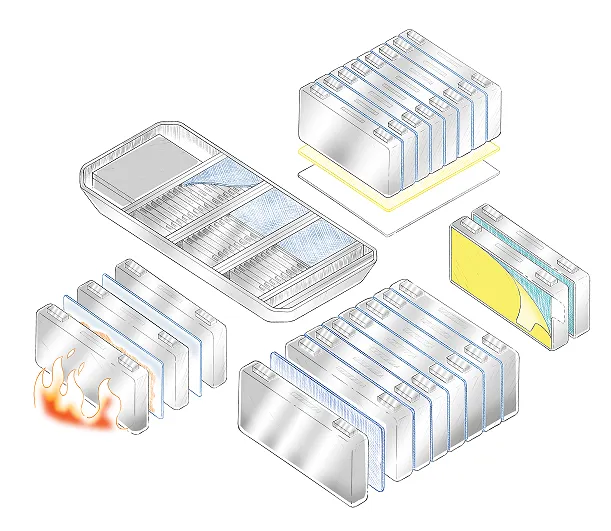

Multi-Layer Laminated Constructions

While the phrase “together we can do more” is most often associated with teams, the same can also be said for materials. By layering and laminating different materials together – foam to adhesive, graphite to foam, ceramic paper to graphite, or aluminum – engineers can solve complex design challenges that may have otherwise proven elusive had they been limited to a single material.

By combining multiple materials into a single part, not only does it address multiple challenges, it speeds assembly and also simplifies the supply chain. AND, instead of working with 2-3 vendors and 2-3 SKUs – one supplier can manage the entire process.

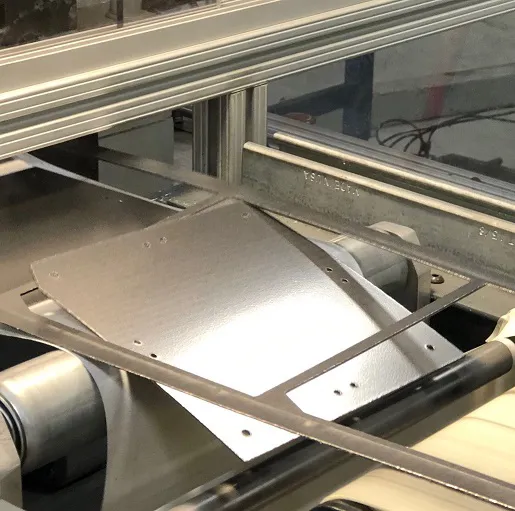

As a vertically integrated converter, we offers an extensive array of laminating capabilities, from inline laminating on our rotary die-cutting presses to hot roll and cold pressure laminating webs that can accommodate materials up to 74” wide.

Performance Materials

When you choose to work with us during the early stages of your project, you’re able to leverage our unparalleled network of industry suppliers and manufacturers from the very beginning, essentially making our connections your connections.

For example, on the adhesive front, we’re both a 3M Preferred Converter and an Avery Dennison ADVantage partner. We also have decades-long relationships with North America’s premier manufacturers of foams, films, flexible graphite, metal foils, insulation, and more. What all this means for you is expert advice and timely answers to your materials selection questions.

Some of the high-performance materials we laminate, die-cut and use our other vertically integrated processes to convert our customers’ EV design concepts into reality include:

Ceramic Papers and Blankets | Ceramic Papers with Mica Laminate | Aerogels | Flexible Graphite | Microcellular Polyurethanes | Polypropylene Electrical Insulation | Polyamide Papers | Silicones